The craziest bathroom floor we've ever done!

It’s been a long journey on this project and it seems we’re finally closing in on the finish line. This one was outside of our wheelhouse in many ways, as it was a whole house remodel.

Big projects aren’t something we traditionally do because we are two people. Most don’t want to wait months for us to complete our tasks. The public doesn’t understand that on projects like this one, they don’t go quickly…adding to the unlikelihood we participate in projects like these.

But this homeowner wanted things done right, he wasn’t in a rush and our personalities meshed. We “shared values” as I always like to say. That really is my number one qualifier.

Although this project wasn’t one we would usually take on, it was intriguing because we were able to work with some of the most interesting material and exercise our mental capabilities on some of the biggest tile installation challenges:

Multiple heated floors, multiple curb-less/zero entry showers, LARGE format tile, odd shaped glass tile, mosaic tile, LOTS of self leveling, rebuilding rot, custom made to order tile, “mud” work, SPECIFIC patterns…not to mention sheet rock, additional carpentry….we generally handled everything that had to do with the areas we were working on and things the homeowner couldn’t find anyone else to do.

Jason did a lot of consulting and helped the homeowner in many ways, bring this thing to the finish line.

We aren’t quite done at this house, but it seems to be almost there.

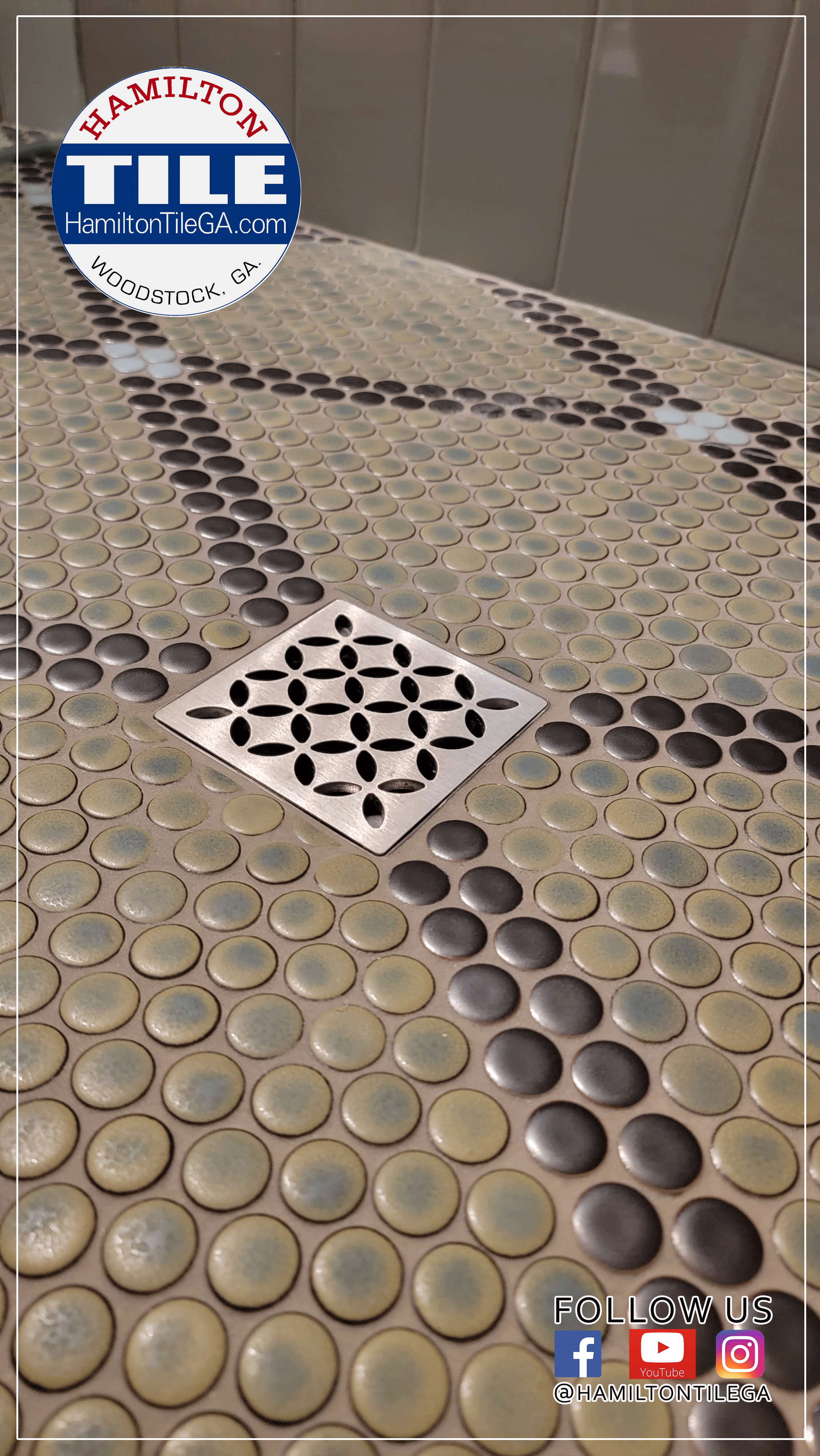

One of the most amazing projects we took part in was this custom, hand made mosaic penny round pattern floor.

We had 3 kinds of penny round tiles: blue, purple and green. We took them apart and re-assembled them to make a Victorian style pattern. A real CLASSIC look.

We made the pattern in a separate room and moved it into the bathroom to set.

But before we could do that, we “packed” the floor with a sand mix to make sure we got the level right.

The homeowner wanted a curb-less, zero entry shower, so we had to raise the level of the floor in order to get the slope for inside the shower.

The old school method of “Packing” this floor was the perfect candidate to accomplish this.

You see, there were 2 other floors and the homeowner wanted them to be at all the same level. The difficulty was that the hard wood floors were already in.

So, Jason did the math and used his skills to make it all work. No step up or step down transitions.

Everything had to be done METHODICALLY. This doesn’t get done until this over here is done…

A curb less or zero entry shower, in this scenario, meant EVERYTHING had to be waterproof.

We also added a small curb in order to contain water that could potentially escape because the bathroom was so small that there was a door VERY close to the shower.

We waterproofed the whole room using Schluter products put together with Ardex 8+9 and then painting everything with Ardex 8+9 for good measure.

We then set the penny round pattern, moving the penny rounds (which were laid out in the other room) into the bathroom.

By the time we were done we could repeat the pattern in our SLEEP!

The best part, is we grouted this whole project (including this floor) with epoxy grout.

We did this because epoxy needs the least amount of maintenance compared to cementitious or other grouts. It’s the toughest stuff out there.

We had never done a floor like this and we are quite proud of it. I think it will really be another fascinating finish in this home. THERE ARE SO MANY HERE!

I’m so happy to be able to get so much great content out of this project. We’re thrilled to see how it’s all turning out.

This project is a testament to Jason’s skill and mastery of the tile trade. To be able to see this project from tear out to completion, that is what I’m most impressed with. For him to have the vision to see how it will all turn out, IMPRESSIVE.

As always, grateful for the opportunities, happy to help another homeowner,

CHEERS,

Ben

Jason finishing up epoxy grouting with Laticrete’s Spectra Lock Pro Premium.

Packing the floor.

An “old school” technique that still has it’s place!

Waterproofing EVERYTHING.

Notice the smooth transition to the foyer floor…A lot of planning when into that!

© 2023 HamiltonTileGA.com

Ben here, the curator of this site. This site is here not only as an informational tool for you, but also a promotional tool for our company Hamilton Tile, LLC. Tile and bathroom remodeling is what we do for a living, it’s how we support our families. If you are in our local area and you have a project that you think we would be a good fit for, please contact us. My e-mail is Ben@HamiltonTileGA.com and our office number is 770-675-6916. We would love to display our brand of quality and service in your home. Please follow us on Instagram and Facebook @hamiltontilega . Thanks for being here. For podcast or radio interviews contact us using the contact info above. Please consider DONATING BELOW. THANKS! Just click the photo.